There are several benefits to choosing a rotary-spreader. Rotary spreaders save you time because they spread the product over a wider strip, per pass, allowing faster treatment of the total area. And rotary spreaders are compatible with many products, including products with larger granules.

Pitfalls to watch for.

Uneven distribution can be a problem with fertilizer and weed control combination products. Small, light-weight particles fall to the ground, while larger, heavier ones are thrown farther out, making it difficult to disperse product evenly. To get enough product applied on your entire yard, it is important to consistently overlap the right amount of product on each pass. You must also prevent the product from being thrown onto areas where it should not be applied: sidewalks, driveways, patios, play areas, sensitive landscape plants, gardens, etc. In addition to managing the swath pattern, you must be aware of cross winds that could possibly blow granules off-target.

Calibration of a rotary spreader is a two-part process.

Part 1 – Measurement of the Swath Width and Distribution Pattern

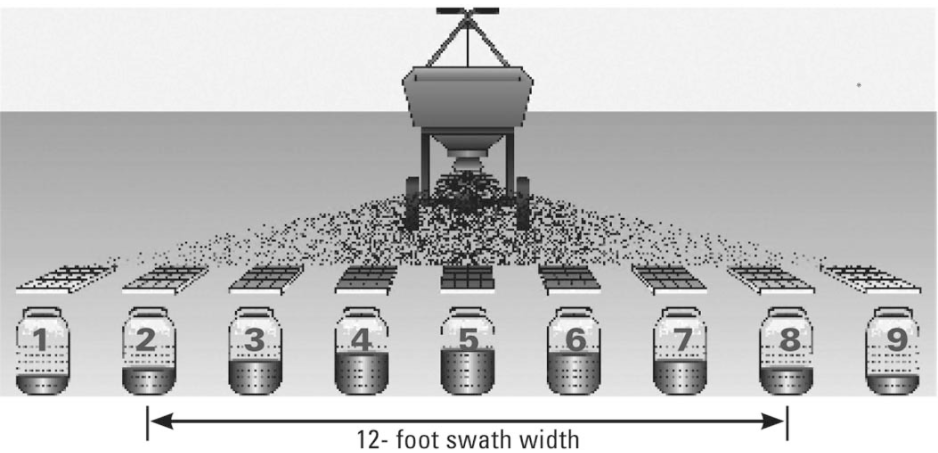

A good way to check the distribution pattern is to use a row of shallow boxes, trays, or pans in a line perpendicular to the direction of travel. Use 7-9 boxes that are identical in size, 1 to 2 inches deep, with an area of at least 1 square foot.

Step 1. Place one box in the center and space the remaining boxes on 2-foot centers to either side of the center box.

Step 2. Pour some product into the spreader and follow the setting recommendation on the label. Make 3 passes over the boxes—always from the same direction.

Step 3. Record the weight of granules collected from each box or pour granules into a jar marked with the box number. When you line up the jars in the same order as the collection boxes, you will see the distribution pattern. The center jar should have the most product, with amounts tapering off evenly on each side. If the pattern is not even on each side, follow the manual instructions for adjusting the spreader and then repeat Steps 2 and 3 until the spreader is applying the material in the most uniform pattern possible.

Step 4. Find the jars to each side that have half the amount in the center jar. The distance between the boxes represented by these bottles is the effective swath width.

Part 2 – Determine the Application Rate

Because the distribution pattern of a rotary spreader is rarely uniform, it is best to make two passes over a treatment site. Therefore, rotary spreader calibration should be based on applying one-half the label rate. Using the full label rate in two passes would result in application of a double dose of product.

Step 1. Weigh out enough product to load the spreader for a calibration test over a distance that can be easily converted to 1,000 square feet based on the spreader’s effective swath width (see the following table).

Distance and Effective Swath Width for Rotary Spreaders to Equal 1,000 Square Feet.

| Effective Swath Width (feet) | Distance (feet) |

| 6 | 167 |

| 8 | 125 |

| 10 | 100 |

| 12 | 84 |

| 14 | 72 |

Step 2. Select a test setting to deliver one-half the labeled rate (Note: Spreader settings are not linear, so using a number half the number recommended on the product label will not result in half the application rate. You may need to experiment with the equipment.)

Step 3. Apply the material over the measured distance and weigh the product remaining in the spreader. The difference in pounds should be within 10 percent of one-half the pesticide label rate. Adjust the size of the gate opening until your application rate is in the right range.

Once spreader is calibrated, determine how much to apply.

Label application rates for granular products are usually stated in pounds of product per acre or per 1,000 square feet. Whether you use acres or 1,000 sq. ft. in your calculations, be consistent. Divide square feet by 43,560 to convert to acres; multiply acres by 43,560 to convert to square feet. To determine the amount of product to apply, multiply the area to be treated by the application rate. Maintain your spreader through lubricants such as Paraliq.

Calibrate, spread, enjoy a beautiful yard.